A riveting behind-the-scenes look at the design-build approach for one of the largest infrastructure projects ever completed in the U.S.

The “new New York bridge”, officially named the Governor Mario M. Cuomo Bridge, replaced the Governor Malcolm Wilson Tappan Zee bridge. For many the bridge will always be referred to as simply the Tappan Zee. At one point the New York Times referred to it as the ‘Bridge of Grand Ambition.” Whatever you choose to call it, most agree it’s an engineering and construction feat.

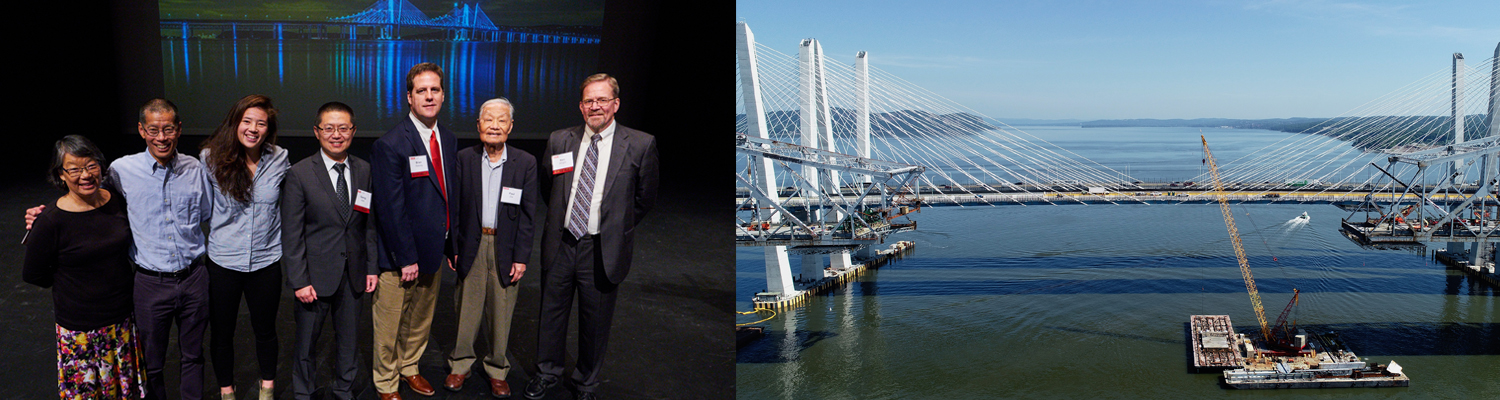

The 2018 Paul Zia Distinguished Lecture series, attended by almost 600 engineers, faculty and students, featured the iconic bridge. Presenters included Mr. Brian Keaney, PE (BSCE 1993, MSCE 2000), Geotechnical section Manager with HDR; Mr. Gang Jiao, PE, Director of Design Engineering with Fluor; and Mr. Ken Wright, PE, Northeast Area Principal Bridge Engineer with HDR.

The Zia Lecture has reached the point of, ‘Of course, we are going to see another miracle this afternoon.’

Donald Kline, retired P.E. (BCE 1953)

Member of the first Zia Lecture Committee

By the time Governor Andrew Cuomo pushed through legislation in late 2011 to begin construction of the first design-build bridge in the state, the project had been in discussion for more than a decade, and over 150 concepts had been considered. However, after the request for proposals, which required a 100-year service life for the new bridge, was released in March 2012, things moved along remarkably fast. The contract was awarded in July of the same year, to Tappan Zee Constructors, LLC, a consortium of design, engineering, and construction firms.

A FEW INTERESTING FACTS ABOUT THE BRIDGE

- Built to replace the existing Tappan Zee bridge over the Hudson River

- Traffic on the old bridge was exceeding capacity by 40%

- Maintaining the old bridge had already cost $1 billion

- Estimates to maintain the old bridge were an additional $750 million/year

- The new bridge cost $ 3.98 billion to design and construct

- 1 mile two-span bridge with four lanes of traffic on each span

- 330,000 cubic yards of concrete poured during construction

- More than 1,000 piles driven into the Hudson riverbed

- 192 cables on the bridge; 14 miles of stay cable total; 700 miles of strand in the cables; 49,000 miles of wire in total

- New bridge can handle 140,000 vehicles a day

“My best work is underground.”

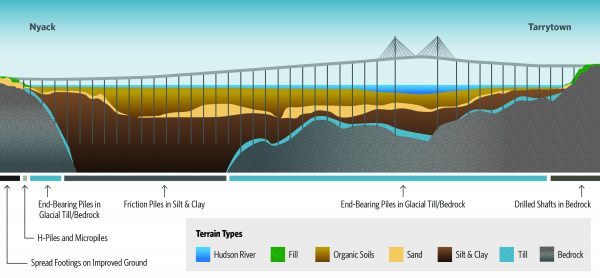

CCEE Alumnus Brian Keaney (BSCE 1993, MSCE 2000) served as deputy lead foundation engineer. He described the geotechnical challenges of building the bridge across the Hudson River, and while he provided numerous engaging photographs of the construction and finished phase, he joked with the audience that his best work was underground.

Explaining that numerous soil samples were required to characterize the subgrade and topology of the riverbed underneath the bridge, he provided a graphic showing the various types of foundation elements used. They included H-piles, micro-piles, friction piles, end bearing piles, drilled shafts, and spread footings. Aggregate piers and earthquake drains were employed for areas susceptible to liquefaction. Roughly 80,000 tons of steel was employed and standing the piles end to end would stretch 50 miles long.

Pre-fabricated, repetitive elements to meet performance.

Ken Wright served as design manager for the bridge project. He reminded the audience that part of the structural design considerations included making sure that as much of the work as possible could be done off the water, for both safety considerations and cost efficiency. The project made extensive use of pre-fabricated and repetitive elements, which were constructed off-site and brought to the construction site by barge.

The substructure consisted of precast pile caps that were infilled with concrete batched on-site. The superstructure consists of an aesthetically pleasing 5 span steel girder assembly with the iconic main span being a twin-cable stay.

The difference between low-price and low-cost.

Gang Jiao, PE served as Tappan Zee Constructors’ Design Engineering Manager from early in the proposal phase, shaping the winning design-build strategy, and executing the design and construction. He began his talk by defining the difference between “low-price and low-cost”. “Low price means you do the same work, but you bid low and we all know that is not sustainable,” Jiao said. “Low cost means you need to be creative and innovate to be competitive, versus simply underbidding.”

The construction approach included off-site fabrication and modular assembly. Utilizing a large crane that had been built previously for a bridge project in Oakland Bay, and was owned by two companies who were part of the Tappan Zee consortium, led to the ability to lift larger spans and heavier sections creating an advantage in construction speed and cost savings. The modular approach also minimized the need for dredging, which led to decreased costs, and lessened environmental impacts.

Find out more about the Zia Lecture, including a sneak peak at next year’s topic.

For more about the bridge including lots of photographs, visit the project site.

To see a few more photographs of the lecture and reception visit our Facebook page.