Sensing and Monitoring

How can we detect and quantify damage in structures through physical measurements and mathematical modeling?

During their service life, infrastructure are subjected to mechanical and environmental loading which can adversely affect their performance and serviceability. To monitor the health of infrastructure sensing and monitoring techniques are used to detect and quantify deformation, damage, and degradation of infrastructure. At NC State, multiple faculties and students work towards the development of advanced sensing and monitoring techniques. We develop techniques to monitor physical, chemical, and electrochemical processes and degradation at material level as well as monitoring techniques for full scale structures for example to detect cracking of reinforced concrete structures, scour in bridges, de-bonding of fiber reinforced polymers from their substrates, and identifying the loss of prestressing forces.

We develop advanced analytical, computational, and experimental methods for quantitative imaging of concrete and other porous materials. We use Electrical Impedance Tomography (EIT) to visualize damage and moisture flow within these materials.

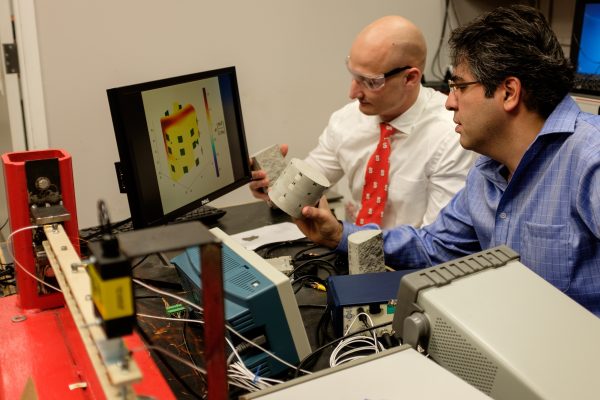

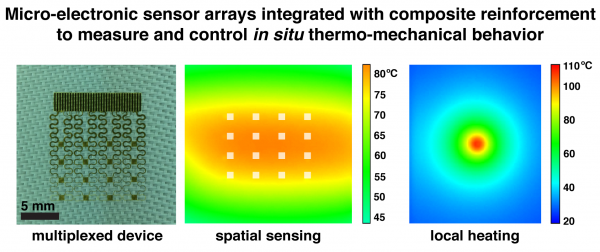

Multiplexed array of micro-electronic sensors in a glass-fiber reinforced polymer (GFRP) composite to accurately monitor spatial distribution of temperature/strain and locally heat through in situ electrical resistance.”

Multiplexed array of micro-electronic sensors in a glass-fiber reinforced polymer (GFRP) composite to accurately monitor spatial distribution of temperature/strain and locally heat through in situ electrical resistance.”

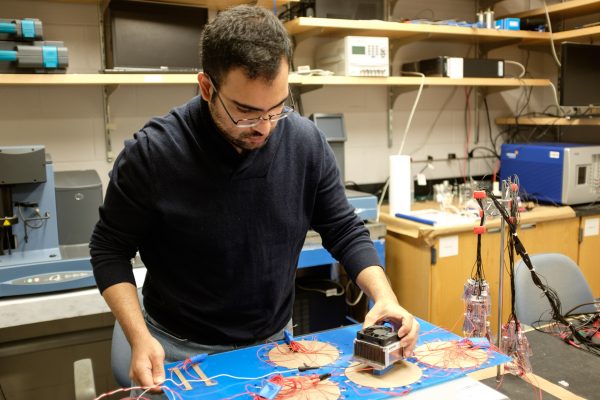

Testing of functionally layered large-area sensors, called sensing skin, for structural health monitoring. Sensing skin has many applications in continuous monitoring of critical building components, oil and gas pressure vessels, storage tanks, nuclear containment and waste storage facilities, aeronautic structures, and military and defense structures.

We development new methods and materials for printing sensors in our laboratories. Printing sensors allows us to design them for complex structural shapes.