Stewart Theatre in the Talley Student Union was near capacity on Monday, September 18th, 2017, at the 16th annual Paul Zia Distinguished Lecture. Almost 700 attendees listened to three panelists describe their role in the design and construction of the Wilshire Grand Center in Los Angeles. At 1,100 feet, the skyscraper is the tallest building west of the Mississippi, and one of the tallest ever built in this country. It was developed at a cost of more than a billion dollars. Configured to maximize views with floor to ceiling glass in the hotel rooms and offices, the mixed-use site is an iconic addition to the visual character of downtown Los Angeles and considered a design and engineering feat. This year’s program featured three speakers, including CCEE alumnus Todd Whisenhunt (MSCE 2004).

“There has not been a new skyscraper in L.A. for 30 years.

We wanted to make an impact on the skyline, and we wanted the design to be fresh,

so we hired three young architects straight out of school,

and married their genius and creativity with our conventional wisdom.” Tammy Jow

“We wanted to make an impact on the skyline.”

The symposium began with a presentation by Architect Tammy Jow, the Project Director and Senior Designer with AC Martin, the architectural firm responsible for design. “We wanted to create the new nucleus of L.A. with both indoor and outdoor experiences. One of our big ideas was to put a sky lobby on the 70th floor, so that everybody who stays at the hotel gets the views,” she continued. A high-speed elevator moving 1600 feet per minute takes visitors to the top of the building in less than one minute.

Jow says the project was always on a fast track, which was one of the factors that led to what she called “another big design idea” – efficiency. This design approach had ramifications for everything including the size of the ducts, which were kept small to save core space for elevators, to the specification of bathrooms, which could be pre-fabricated.

The iconic building has a “sail” on top that rises 100 feet above the 70th floor sky lobby, and finally a spire that extends another 173 feet into the air. “When we originally conceived the idea for the sail we designed double trusses. Then structural engineering came in, and reality struck,” Jow relayed, eliciting a collective laugh from an audience consisting primarily of engineers, before she turned the podium over to structural engineer Todd Whisenhunt.

“You get to know your building better.”

Todd Whisenhunt, a CCEE alumnus who is now Vice President with Thornton Tomasetti, began his presentation by explaining the structural scope of the massive and complex building. The basement, five floors deep, supports the 73-floor tower and is also laterally engaged with the structure. “With any tall building you began the lateral design with wind parameters and then move to the seismic design,” Whisenhunt explained. “We designed for both strength level wind and service level wind,” he continued. In this case, strength level referred to a 1700 year Mean Recurrence Interval, which means standing up to winds of 115 miles per hour. “We also needed to plan for service level winds, meaning we did not want people inside to feel the structure move even in low level winds,” Whisenhunt explained. The team utilized simulation models and also performed a wind tunnel study using a model of the Wilshire Grand.

Of course it’s widely known that the Los Angeles area is considered one of the most earthquake prone areas in the country. As Whisenhunt began explaining the approach to seismic design, he showed the audience a Faults and Seismic Activities map of the area. He explained that the team used Performance Based Design (PBD) as opposed to code-based design because PBD allowed for more innovation.

“In the long run you learn more about your building using Performance Based Design,” he said. However, while allowing for more innovation, PBD demands significantly more analytical effort than code-based design. The team used computer models incorporating time-history records from 11 actual earthquakes to simulate the shaking that would occur in the Wilshire Grand. And of course they had to plan for extreme seismic conditions, referred to as Maximum Considered Earthquake (MCE) or as Whisenhunt pointed out what is often called “the big one.”

“It’s all about keeping things consistent.”

Brendan Murphy, Vice President and Operations Manager with Turner Construction, finished the Lecture program by explaining the challenges of demolishing the 1950s era building that stood where the new Wilshire Grand was to be built. Because of seismic considerations, the existing building could not be imploded, but rather had to be demolished floor by floor. “We created a system. We were able to take down one floor every five days, and we recycled 100% of the concrete and structural steel,” Murphy explained. The demolition took 12 months, and during that time the construction firm created a sequence for the construction phase that worked on a four-day cycle. “The trades embraced the cycle, and even with 1200 trades people employed on the construction crew, we only got off the building cycle three times,” Murphy said. He likened it to an orchestra, and at one point said “and the civil engineers tie the whole orchestra together.”

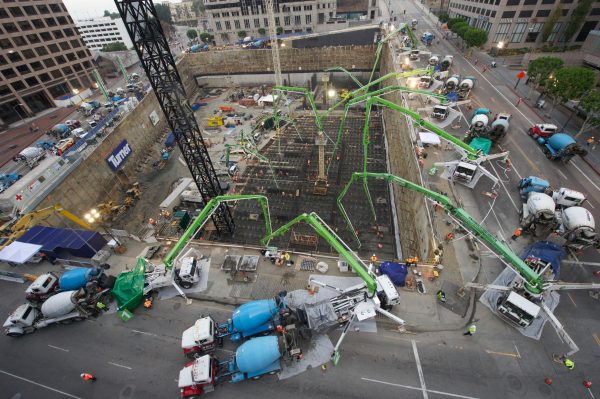

After the demolition came another record setting attribute of the Wilshire Grand Center. Pouring the mat, which Murphy referenced as “17 feet and 6 inches of concrete cake” took 18.5 hours which is the longest mat pour in recorded history.

Murphy cited the importance of efficient communication between the architects, structural engineers, and construction project managers, referencing a 58-minute meeting that took place every Tuesday morning from the design phase through completion. “We found a third floor empty office space right across the street from the site, and we all co-located there. We had spaces for all the trades, Thornton Tomasetti, and the architects,” Murphy said.

You can find out more about The Paul Zia Distinguished Lecture series here, including a look at next year’s topic.

“We had a lot of firsts this year, including the first time the speakers have gone to a class to speak,” said Zia Lecture Committee Chair Christine Nguyen Herrick, P.E. (BSCE 2011) . We coordinated with CCEE Lecturer Steve Welton, to have a panel discussion as part of the Steel Design Course. It’s also the first time that we advertised to the E101 freshman engineering class.”