Large Structural Systems Laboratory

The Large Structural Systems Laboratory has 4,500 square feet of reaction floor space. The laboratory allows CFL researchers to test large to full-scale structural systems under of static, dynamic, and environmental loading conditions. CFL personnel are knowledgeable on the use of many materials such as fiber reinforced polymers (FRP), conventional and high-strength concrete, steel, masonry, and wood. The laboratory is served by two 20-ton overhead cranes and has a MTS hydraulic system capable of 90gpm peak flow capacity.

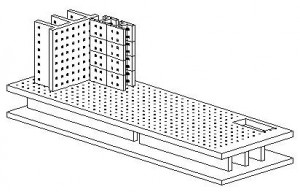

The reaction floor is a 13-foot-thick cellular box, which is about 120 feet long by 40 feet wide. It is complemented by one fixed and one modular 25-foot-high reaction wall. This configuration allows testing of large structural systems under one and two directional horizontal loading.

State-of-the-art equipment for testing high-strength materials and high-strength, large-scale structural systems is available, including:

- numerous reconfigurable test frames with up to a 24-foot vertical clearance;

- a column-testing frame with a 400-kip force capacity and 25-foot vertical clearance;

- static and dynamic actuators with capacities of 22-, 55-, 110-, 220- and 440-kips and up to 40in. displacement capability;

- a 2000-kip Baldwin closed loop compression machine

- a 220-kip closed-loop servo-hydraulic universal testing machine; and

- a 20-kip electro-mechanical universal testing machine.

Perhaps the most unique capability of the CFL is its ability to test structures under a combination of physical and environmental loading conditions. The CFL has a walk-in Thermotron environmental chamber on the laboratory strong floor. The environmental chamber contains 1512 cubic feet of test space (18ft x 8ft x 8ft). The chamber is capable of thermal loading from -68C (-90F) to 85C (185F), humidy control from 20% to 95% relative humity (limited by +7C to 65C dewpoint range and a +70C maximum dry bulb temperature), and salt or fresh water spray up to 20gpm. The chamber was designed to transition from +85C (185F) to -40C (-40F) or from -40C (-40F) to +85C (185F) in 24 +/- 1 hour with 55,000lbs of steel (non-humidity). The chamber is electronically controlled and can be programmed for complex environmental loading sequences or cycles. Specimens subjected environmental conditions can be simultaneously loaded using high-force hydraulic actuators. Other environmental testing equipment includes a rapid freeze-thaw machine for freeze-thaw testing of concrete.

For seismic evaluation of structural materials and systems, the CFL is equipped with a single-axis shake table. The shake table has an 8ft x 8ft steel table with a 40,000lb vertical capacity, a 10in. stroke, and a 800mm/s peak velocity.